Voltin & ARM Hub

How an Idea Became a New Standard for Building Assessment

Background

When Voltin was founded just five years ago, it emerged from a very real frustration inside Australia’s building industry. After more than a decade conducting specialised building inspections, founder and director Steve Thornton had seen the same issues play out time and time again: inconsistent inspection practices, subjective assessments, and a lack of reliable data that left both asset owners and residents with little clarity about the true condition of their buildings.

Voltin was created to change that. What began as “the germ of an idea,” as Steve puts it, was a simple but ambitious vision to replace risky, slow, and manual façade inspections with an intelligent, automated system capable of capturing and analysing a building’s condition with the same detail as a medical scan.

Around the same time, ARM Hub had just been established to help Australian companies bring advanced manufacturing and digital technologies to life. Voltin became one of ARM Hub’s very first industry collaborators, and the two organisations quickly found common ground: a shared belief that innovation wasn’t just possible, it was necessary.

In our earlier impact study, we introduced Voltin at a pivotal moment in their journey. The transition from a promising prototype to the commercial readiness of the AutoBAT system. At that stage, Voltin had successfully completed the design-to-manufacture pathway with ARM Hub and QUT, securing CASA approval and releasing AutoBAT 2.0, an upgraded model shaped by rigorous testing, industrial design input, and early-stage AI capability.

This new chapter tells the story of what happened next.

The Challenge: Scaling Innovation in a Shifting Industry

Australia’s built environment is facing a structural challenge. In the last 25 years, weaker compliance and construction standards have contributed to a growing number of defects in high-rise buildings, particularly in the residential sector. Most buildings, to some degree, leak, corrode, crack, or degrade. And while these issues are predictable, the inspection methods historically used to detect them have not kept pace.

While Voltin had proven the technical viability of the AutoBAT, the next challenge was much larger:

How do you scale a world-first system in an industry grappling with longstanding structural issues?

Over the past four years, building owners, inspectors, and developers have faced intensifying pressures:

Worsening defect rates in high-rise residential buildings

Increased public scrutiny of construction quality

Aging commercial and industrial assets

High costs and risks associated with manual inspections

Limited pathways for drone-based inspection in urban areas

Voltin had a proven technology, but the market needed a more complete, intelligent, and scalable solution. One capable not just of capturing defects but of becoming a trusted tool across the entire building life cycle.

The question was no longer: “Does AutoBAT work?”

It became: “How far can this innovation go?”

The Solution:

To meet this challenge, Voltin strengthened, deepen, and expanded its capabilities. Since our previous report, Voltin has worked on three major project phases that have shaped their evolution:

1. Deepening the Technical Foundations

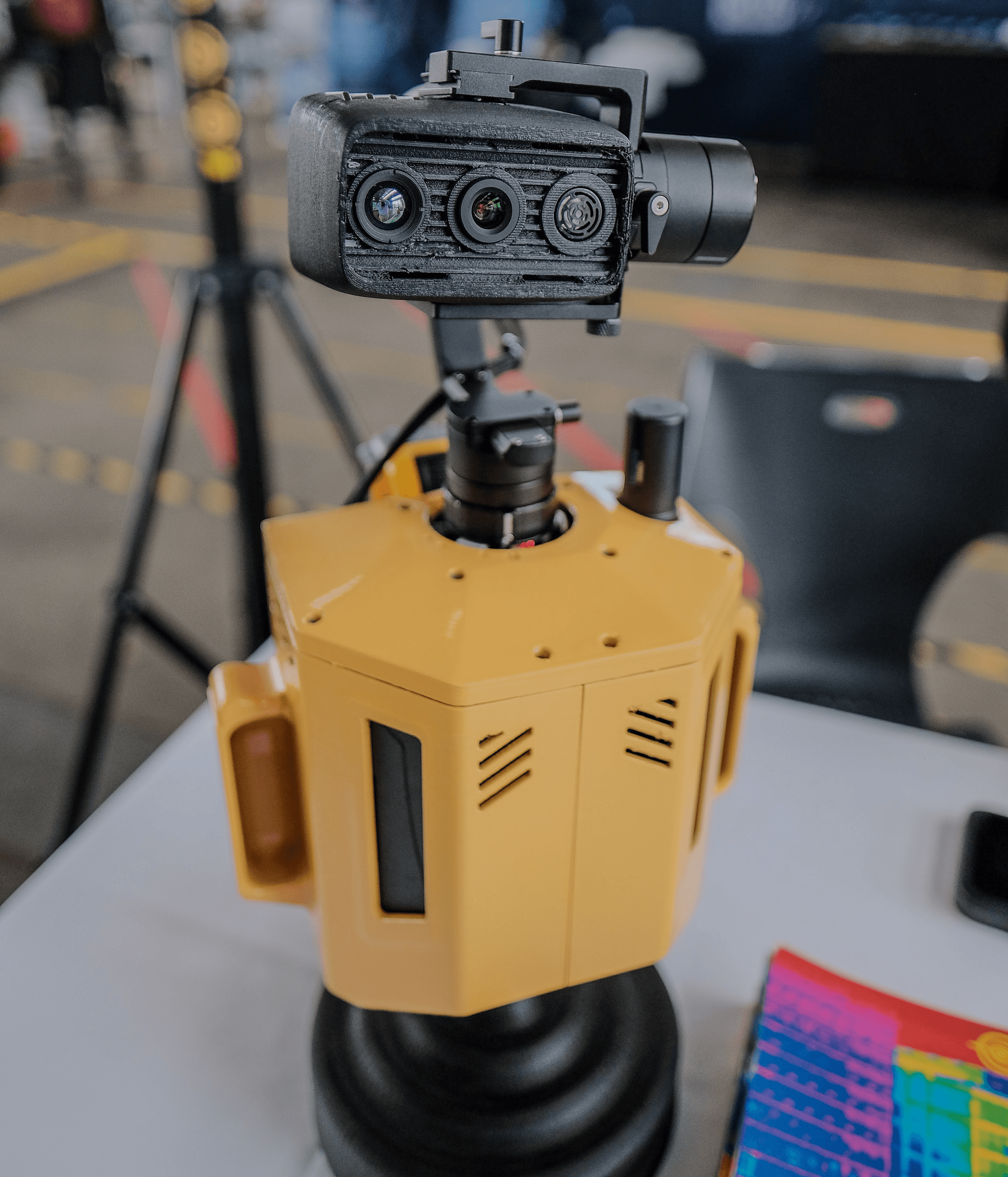

The early design work with ARM Hub and QUT provided the technical architecture for AutoBAT. Building on that foundation. Now Voltin examines how the system could deliver complete and repeatable building coverage using advanced imaging, sensor fusion, and AI-driven analysis.

As Steve Thornton describes, the transition was profound:

“We’re no longer just inspecting buildings, in essence, we’re giving them an MRI.”

2. The ARM Hub Sprint: Accelerating Intelligence

In 2023, ARM Hub facilitated an intensive 6–9 month Sprint program where the focus shifted from hardware to intelligence:

Software enhancements

Smarter automation

Machine learning integration

Improved computer vision

Faster, more intuitive reporting tools

This Sprint pushed Voltin from an innovative device to an intelligent platform and was the bridge between AutoBAT 2.0 and the AutoBAT 3.0 now in development.

3. Strategic Guidance and Ecosystem Access

Perhaps just as important as the technical work, Voltin credits ARM Hub with providing:

Mentorship

Commercialisation support

Regulatory insights

Connections into advanced manufacturing and AI networks

As one of ARM Hub’s earliest collaborators, Voltin has effectively grown up alongside the Hub.

“They’ve been a collaborator, mentor, advisor, and above all, a connector into the technology ecosystem.”

Impact: From Early Success to Global Momentum

Since our last impact study, the scale of Voltin’s achievements has expanded dramatically.

National Deployment

Voltin has now inspected more than 70 buildings across Australia’s largest cities, covering commercial towers, industrial structures, and complex residential assets.

International Work

Their capability has already taken them offshore, completing specialised work in the Middle East, opening the door to broader international expansion.

Technology Progression

AutoBAT has continued to evolve:

AutoBAT 2.0 refined AI detection, stabilisation and data capture

AutoBAT 3.0, now in development, brings next-generation sensor fusion, advanced imaging, and deeper machine learning capabilities

Where the early systems replaced manual observation, the new systems deliver predictive insights and comprehensive digital records.

Shaping Industry Expectations

Voltin’s technology is now setting new benchmarks for:

Accuracy in defect detection

Building life cycle monitoring

Safe access strategies

Asset management planning

Data-driven decision making

The industry, once reliant on subjective inspections, now recognises the value of full-coverage digital analysis.

A Continued Partnership with National Impact

Voltin’s story is still unfolding, and ARM Hub continues to play a central role in that journey. As Steve Thornton reflects:

“ARM Hub is one of those rare government-backed initiatives that actually works. They’ve been instrumental in helping us grow.”

What began as an innovative concept in our earlier report has now become a maturing Australian success story. One that is gaining national traction, international relevance, and a strong future pipeline.

Voltin is proof of what’s possible when industry, research, and advanced manufacturing capability come together with a clear purpose.

And this impact study marks the next step in that evolving story.